40 Years of Challenge

Red Snowthrowers in the Ever-Falling White Snow

Chapter 1 ──Challenging the Unknown── Building a compact snowthrower that anyone can use with ease.

Although it may be hard to imagine for people who live in places where snow rarely falls, but the job of clearing snow can be exhausting, backbreaking work. Even relatively light, newly fallen snow can weigh around 150 kilograms per cubic meter, while compacted snow can weigh well over 500 kilograms. People who live in snowy regions often have to remove this snow every morning, while during heavy snowfalls they might have to do this several times a day. And if the snow continues to fall, the job may be necessary not only early in the morning, but also throughout the night. Until home snowthrowers became widely available, people often had to shovel snow by hand each and every day, and this was no easy task.

Honda has strived to make people’s lives easier by reducing workloads through products like its general-purpose engines (1953), tillers (1959), portable generators (1965), and lawnmowers (1978). Our goal has been to bring people joy through technology while lightening workloads with advanced mechanization.

“Perhaps we can mechanize snow removal to lighten people’s workloads?”

Honda took on this challenge in 1978 with the idea of trying to develop a compact home snowthrower.

Chapter 1 ──Challenging the Unknown ── Building a compact snowthrower that anyone can use with ease.

Snowthrowers are only used for a short period of time each year during the snow season, yet they must be able to start quickly and perform their jobs in even the most severe winter conditions. If a machine fails to work, the snow won’t wait. That’s why reliability and durability are essential elements in the design of a snowthrower. Snowthrowers also need to be constructed in such a way that they can be easily serviced or repaired in a short time.

Honda’s challenge to create a user-friendly compact snowthrower was beset with difficulties from the start. As computers were still rare at the time, development proceeded based on repeated trial-and-error testing in the field. Besides carrying out development work in Japan’s regions of heavy snowfall during the winter months, the team even went so far as to travel to the southern hemisphere when Japan’s snow season was over, or even conducted testing by using sawdust instead of snow.

Sawdust being used for testing instead of snow.

Sawdust being used for testing instead of snow.

Chapter 1 ──Challenging the Unknown ── Building a compact snowthrower that anyone can use with ease.

After two years of intensive development work, the first HS35 model went on sale in 1980. Its rugged four-stroke engine started easily, even at minus 25 degrees Celsius, and, compared to the two-stroke engines that were common at the time, offered many advantages in terms of the environment, fuel economy and low noise. On top of that, this new home snowthrower could also be easily operated, and stopped automatically whenever the user let go of the clutch lever mounted on its control bar.

The HS35 was accurately targeted at user needs, and soon established a strong reputation in both the United States and Japan. Having opened the door for snowthrowers with the compact HS35, in its highly recognizable Honda Red livery, Honda’s Power Products division then took on the next great challenge.

HS35

HS35

Chapter 2 ──The Challenge of Peak Efficiency── Fine speed control becomes the key to top performance.

Once Honda’s first snowthrower model, the HS35, demonstrated the effectiveness of its compact design, it was time to meet the market’s demands for more powerful high-level models. In Japan, that also meant models better suited to the regionally unique characteristics of Japanese snow. This then became the start of Honda’s challenge: To create compact snowthrowers that would be even easier to use.

The HS35 was a semi-automatic model that wasn’t equipped with independent drive. Honda now devoted its attention to the drive unit. Independent control of the drive system was essential in unstable snowy environments that may not necessarily be flat. Easier speed control would also result in more efficient and compact snowthrowers that would be better able to do the job of clearing snow.

Usually a multi-gear transmission would be used to control the drive speed, but it’s more difficult to easily and steplessly adjust the operating speed. Honda’s response was to develop a new friction disk transmission mechanism that would be able to control not only the snowthrower’s speed, but also both its forward and backward motion, by moving two disks positioned at a 90-degree angle to each other up and down together.

This new transmission was first introduced on the HS50, which debuted in 1982. Various design modifications were subsequently adopted, including a self-propelled type that incorporates crawlers, and a two-stage snowthrowing design that first collects the snow, then throws it. Honda’s snowthrowers began to acquire a reputation for high performance, and from the mid-1980s onward the lineup was expanded to include both medium- and large-sized models.

HS50

HS50

Chapter 2 ──The Challenge of Peak Efficiency ── Fine speed control becomes the key to top performance.

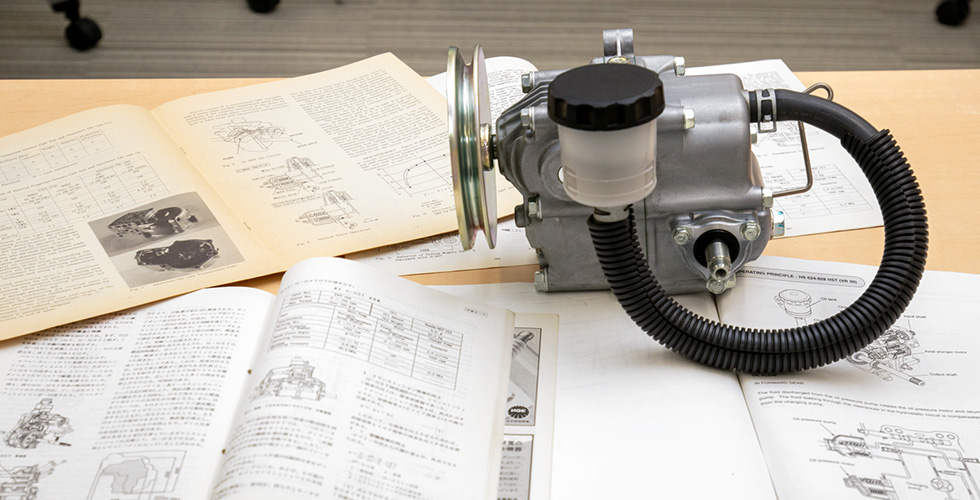

Honda’s ongoing challenge was to pursue greater efficiency for even greater ease-of-use. As a result of gradual improvements made to the friction disks and the study of innumerable possible advances, including a Continuously Variable Transmission (CVT), Honda concentrated on the development of a continuous speed Hydrostatic Transmission (HST) that used hydraulic control to achieve the desired fine adjustment of torque and speed in the lower speed range. HSTs had been used commercially in large construction equipment, but there were no compact versions that could be adapted for use in something like a home snowthrower. The HST that Honda was developing for its snowthrowers would not only have to be compact, but also able to operate in extremely cold environments.

Although the early prototypes faced numerous problems and sometimes failed to work at all, the development team persisted in their efforts, leading to the first commercial use of an HST on the HS660S/870S snowthrower models that were released four years later in 1989. The new HST system allowed continuously stepless fine-adjustment of the drive system’s speed with a single lever, providing stable operation that remains popular to this day.

Smaller snowthrower version of HST

Smaller snowthrower version of HST

HS660S

HS660S

Chapter 2 ──The Challenge of Peak Efficiency ── Fine speed control becomes the key to top performance.

Many people became instant Honda fans after experiencing for themselves how easy it was to use an HST-equipped snowthrower. Later, as the work of snow removal became smoother and easier, the next step was to help people move larger amounts of snow with even greater ease. However, in order to efficiently remove large quantities of snow, a certain level of experience and intuition would be required to carry out the job relative to the volume and type of snow.

Honda continued to take on a challenge that no one else in the world would face: Enabling easy and efficient snow removal, regardless of the operator’s experience.

Chapter 3 ──Honda’s Challenge to Be First in the World──

Honda snowthrowers take the lead in snow removal

with world-leading technology.

Although Honda’s new design innovations greatly increased operating efficiency, snow removal still required visual confirmation of the direction and range of the actual snow throwing. Serious consideration needed to be given to the overall operating environment, and snowthrower operation needed to be simplified. Further, if operation could be automated to some extent, even easier and more efficient snow removal work would be possible.

Honda’s challenge was to achieve something that no one else in the world had ever done: Create a snowthrower that works efficiently with operation easy enough for anyone to perform.

Released in 2001, the HS1390 was the world’s first hybrid snowthrower,* using separate electric motors for forward movement and a gasoline engine to power the actual snow throwing machinery. ECUs on the two side-mounted electric motors allowed for automatic adjustment of speed and easier maneuverability. Automatic speed controls that no one else had ever even attempted to produce seemed like the apex of Honda snowthrower technology, but the company yet again set itself a new challenge; this time in the pursuit of fully electronic control.

* Honda research

HS1390i

HS1390i

Chapter 3 ──Honda’s Challenge to Be First in the World──

Honda snowthrowers take the lead in snow removal

with world-leading technology.

The HSM1590i snowthrower released in 2005 featured independent control of both the electric motors and the engine, making it possible to adjust for optimum snow throwing performance by offering control over not only the speed the tracks, but also the engine’s speed as well as other components.

Medium and large-sized snowthrowers are usually put to use clearing snow from large areas of heavy snowfall, for example ski fields and farmlands. Snow that has piled up high in deep drifts must be gradually stripped away. However, often times the footing may be uneven, requiring the user to closely monitor the tilt of the snowthrower. For complex work like this to be done effectively usually requires lots of experience.

Challenging the unknown, Honda set out to augment this needed experience and intuition with automation, resulting in the development of the Smart Auger System, which effectively automates complex auger operations. This system was first introduced in 2013 on the large-sized HSL2511, which was also the world’s first snowthrower to incorporate fuel injection* for the combined benefits of both superb operation and easy starting.

* Honda research

HSL2511

HSL2511

Chapter 3 ──Honda’s Challenge to Be First in the World ──

Honda snowthrowers take the lead in snow removal

with world-leading technology.

Also released in 2013, the HSS760n, 970n & 1170n snowthrowers introduced Honda’s rugged Cross-Auger system, which featured counter-rotating blades, a technology developed specially for Honda tillers. Compared to conventional augers, the Cross-Auger reduced the tendency of the machine to lift up in reaction to the force of snow removal, vastly improving its ability to dig into hard-packed snow. Besides expanding the possibilities for newer, more compact models, the Cross-Auger also stands out as another new technology unique to Honda Power Products, which continues to pursue the further development of a wide range of helpful multi-purpose equipment.

Chapter 3 ──Honda’s Challenge to Be First in the World ──

Honda snowthrowers take the lead in snow removal

with world-leading technology.

Beginning with the introduction of the basic HS35, Honda’s lineup of snowthrowers has grown to include

medium and large-sized models that all enjoy an excellent reputation for easy operation, incomparable

reliability, and long-term durability both in Japan and around the world. Because of this they have continued

to dominate the top share of Japan’s domestic home snow remover market since 2005.*

* Honda research (on gasoline-powered walk-behind rotary snowthrowers)

Looking back over the 40-year history of Honda snowthrowers, it soon becomes clear that the company has never stopped striving for more, no matter how momentous the technology it developed turned out to be. As long as snow continues to fall, Honda will continue its challenge of top performance.