History

In 1946, a small engine designed for portable army radios was turned into a useful tool for people’s daily

lives.

When I see someone with a problem, I just have to do something for them.

Making people’s lives just a little bit easier.

Always focusing on the human element, we wanted to use our technology to help people in their daily lives.

This thinking gave birth to a vast number of Honda Power Products.

The Dawn

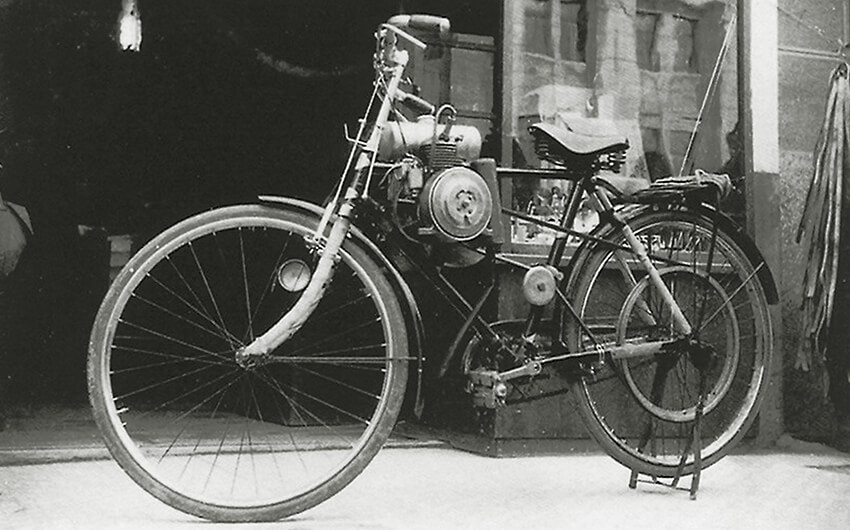

When the Second World War ended in 1945, Japan faced a decisive lack of all manner of goods and materials due to the devastation wrought by the war. These difficult circumstances forced people to struggle just to get by in their daily lives. However, the only means people had to get about in those resource-deprived times were walking, cycling, or taking overcrowded trains. Bicycles in particular became a valued asset that played a critical role in providing transportation for both work and daily life.

Honda’s founder, Soichiro Honda, was born in 1906, the eldest son of a blacksmith, in Komyo Village, in the Iwata District of what later became Hamamatsu City in Shizuoka Prefecture. In 1922, nearing the end of his high school years, the young Soichiro travelled to Tokyo to work for Art Shokai, an automobile service and repair company. In 1928, he was asked to establish a branch of the company in Hamamatsu. He later handed over control of Art Shokai Hamamatsu to his employees, and established Tokai Seiki Heavy Industries with the intention of manufacturing automotive piston rings, becoming the president of the company in 1936.

In 1946, immediately following the end of the war, he founded the Honda Technical Research Institute with the aim of pursuing research and manufacturing of internal combustion engines and various machine tools. That very year, he stumbled across a cache of small engines that had been used as generators to power radios for the former Imperial Army. An idea immediately popped into Soichiro’s mind:

“I can use these to power bicycles!”

He started right to work creating a prototype motorized bicycle, spending all his spare time working away on the

engine as his eyes lit up at the thought of its potential. Eventually, he brought the prototype home and asked

his wife to take it for a spin. “I just made this for you. Here, why don’t you try it out?,” he said.

Since she knew she would have to ride down the main street of Hamamatsu, where many people would be watching, his wife put on her best pair of monpé trousers (Japanese women’s work pantaloons). Soichiro’s wife turned out to be Honda’s very first female test rider.

After riding all the way to Hamamatsu Station and home again, she was shocked to discover that her best pair of monpé were now covered in oil. The reason for this splattering of oily soot was that the unburned fuel/oil mixture had been blowing back through the carburetor. Sheepishly accepting his wife’s judgment that “this will never do; your customers will come back and yell at you,” Soichiro made scrupulously sure that the problem was fixed by the time he was ready to put the bicycle engine on sale.

Word of Honda’s auxiliary bicycle engines spread like wildfire, and their excellent reputation soon resulted in people from as far away as the big cities of Tokyo, Nagoya and even Osaka traveling all the way to Hamamatsu to buy one. However, as his stock of radio generator engines was running out, Soichiro quickly set about making his own auxiliary engine.

The Honda A-Type, Honda’s first totally original product, went on sale in 1947, and soon won a wide following for its affordable price, as well as its ability to run on the poor-quality fuel available at the time.

With the introduction of the A-type, a farewell ceremony was held for the bicycle-mount auxiliary engine.

Founded as a small factory in the town of Hamamatsu, with a starting capital of 1 million yen and 34 employees, Honda’s main product was an auxiliary engine for bicycles. This small company soon became the Honda that we know today.

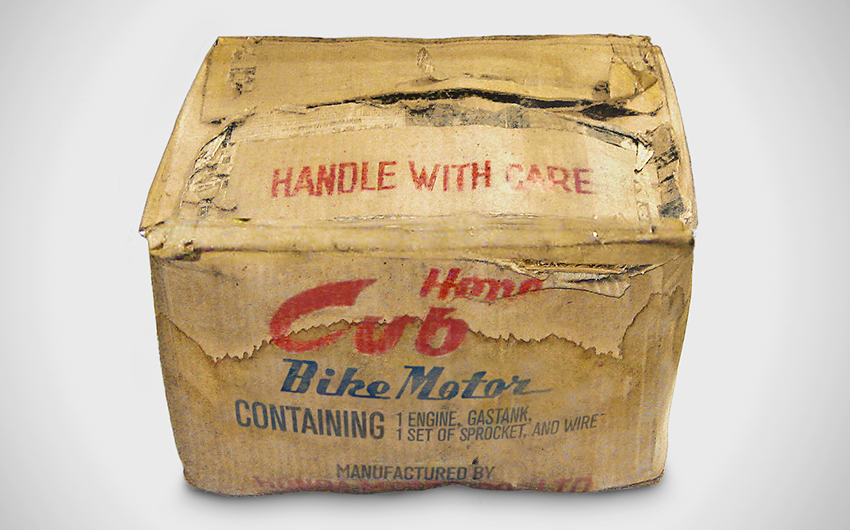

In 1952, four years after the founding of Honda Motor Company, Honda released the Cub F auxiliary engine, which was half the weight of its predecessors while offering significantly better riding and operating performance. Featuring bright red body coloring and a slim white tank, the Cub F also sported a fresh, attractive design. Easy to install even for bicycle shop owners who had no previous experience with engines, the Cub F went on to be sold by 13,000 shops nationwide and reached every corner of Japan.

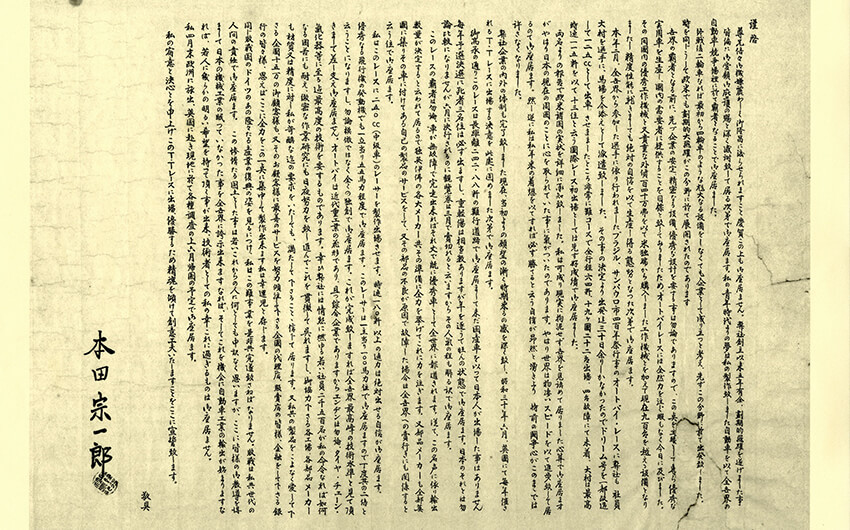

In a 1951 issue of Honda’s in-house magazine, Soichiro announced the concept of ‘The Three Joys:’ the Joy of

Creating, the Joy of Selling, and the Joy of Buying, which soon became the fundamentals of Honda’s philosophy.

“When I see someone with a problem, I just have to do something for them. I want to make people happy. Always

putting people first, I want to make their lives better through technology.” Honda’s subsequent general-purpose

products, including its tillers, lawnmowers, power generators and pumps, became important parts of people’s

lives, reducing labor with technology and making people happier.

(Source: Honda History: Fifty Years of Challenges, Honda Motor Co., Ltd.)

1950 – 1960

In the early 1950s, the chaos of Japan’s post-war years gradually gave way to a steady recovery. But there were still vast challenges ahead, such as increasing food production and building new infrastructure. In the midst of all this, Honda had enjoyed excellent success with its bicycle-mount auxiliary engines. Despite being tiny engines, they were able to make an important contribution to society.

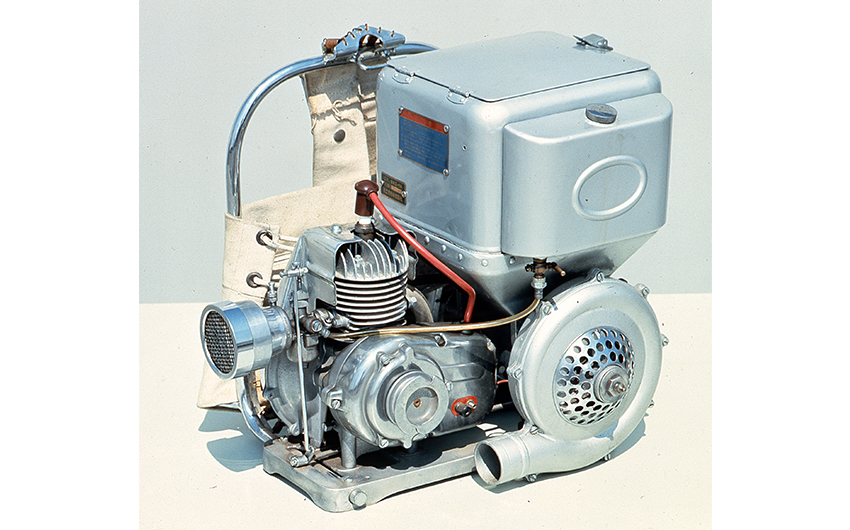

It was around this time that Honda was contacted by a compact farm machinery manufacturer that had heard about the A-type and Cub F engines, and wanted Honda to provide a small engine for a portable sprayer.

Honda took on this request to develop a compact 2-stroke model that it completed late in 1952 and released in 1953 as its first-ever general-purpose engine. This engine was called the H-type.

With an output of only 1 horsepower, the H-type was designed to be as compact and lightweight as possible, and was manufactured using aluminum die-casting, a cutting-edge technology at the time. It was also highly rugged and durable, and could be used for water pumps or power sprayers that could be carried on one’s back, thus helping to lighten the workload of farming.

The lightweight and compact H-hype engine also won an excellent reputation. Still, users continued to ask for improvements, like making it easier to start, quieter and easier to maintain. People also wanted it to be easier to use and not so grimy to handle.

These voices were answered by the T-type engine, which Honda released in 1954. A 2.5 horsepower 4-stroke model, the T-type provided rugged performance at low operating speeds combined with high output at higher revs for an impressive range of versatility when used to power a wide variety of farm machinery.

The year 1954 was also the year that Soichiro Honda declared his intention to participate in the U.K.’s Isle of Man TT motorcycle races. Besides taking on the world by “focusing all of Honda Motor Company’s efforts on winning the crown,” he also had his eye on Japan’s future, announcing that “Honda’s mission is the enlightenment of Japanese industry.”

Honda’s general-purpose engines went from use solely in agricultural and construction machinery to a broad range of applications, including ordinary household implements. As the world continued to change around it, even more power was demanded of its engines. In parallel with such demands were other areas where Honda could show its technological development skills, such as achieving both lower noise and vibration, as well as reducing engine exhaust temperatures.

In 1958, four years after the release of the T-type, Honda released its new high-quality, high-performance VN Series (VNC & VND) of general-purpose engines, with a maximum output of 5 horsepower, as a rugged and dependable power source for use in both agriculture, which was experiencing rapid growth in mechanization, and the construction industry, which was booming with increasing efficiency and productivity. This was the same year that the revolutionary Super Cub motorcycle made its debut, and also the point at which the Honda Motor Company shifted from its founding years into a new era of historic breakthroughs.

Soichiro Honda’s constant desire to provide products that could be more useful and easier to use had led the company to build the A-type and Cub F bicycle-mount auxiliary engines. It then graduated to building the general-purpose H-type and T-type engines. However, now Honda could no longer be satisfied with simply supplying engines to other manufacturers.

In the late 1950s, only 6% of Japan’s approximately 6 million farming households owned a motorized cultivator. At the time, people were starting to say that “These days getting married in rural areas depends entirely on whether or not you have a tiller.” To find a solution to this situation, Honda concentrated on developing a complete product based on one of its compact engines. First, a prototype was made using the VNC engine.

In this way Honda’s research and development shifted with the coming of the 1960s to fully developed cultivators and generators made using its own general-purpose engines.

1960 – 1970

In the mid-1950s, large numbers of people in their 20s and 30s, their prime working years, migrated to the big cities to become the driving force behind Japan’s post-war era of rapid economic growth. This meant that it fell on the women and the older folk to carry on struggling with the heavy load of farm work that they left behind. Keenly aware of this situation, Honda undertook the development of a multi-purpose tiller that could much more easily be used by women and older people. Fueled by the inspiration of total innovation in creating something new that had never existed before—something that would be ten years ahead of its time—Honda came out with its first tiller in 1959, which it called the F150.

Compared to previous tillers, the F150 was compact, lightweight and remarkably easy to use while achieving a highly versatile functionality combined with rugged durability. Even in its styling, the F150’s mechanical parts were fully covered, its modern bodywork coated in a distinctive bright red body color.

At the time, Japan’s total tiller market added up to only a few thousand units per year. However, the F150 recorded explosive sales as soon as it was released, and within the farm equipment industry it soon came to be called the ‘Honda whirlwind.’ Over 20,000 units were sold that year, and production continued for another 13 years with gradual improvements along the way. For farms that had been suffering from an acute shortage of labor, the compact, red Honda tiller proved to be an innovative agricultural machine that revolutionized Japan’s farm work environment.

The next item Honda set out to develop was a portable generator. This was inspired by Sony’s recent invention of a transistorized portable television. Sony needed a power source that would allow it to be used anywhere, and Honda was singled out to undertake development of a portable generator that could be carried by hand.

The compact E300 portable generator was busy in all sorts of scenes.

Although its prototype never reached full production, the knowledge gained from its development was soon used in the development of later models of portable generators, and three years later Honda released the E300 compact portable generator. While ordinary generators of the time were often complicated and hard to start and operate, the little red E300 was small, lightweight, and simply looked easy to use. Just as new electrical devices were gaining popularity in Japan, the E300 marked the arrival of a portable power supply that anyone could use.

The sheer convenience of this compact, quiet and smoke-free generator caused generator sales to skyrocket, whether on construction sites for use in lighting where night work had increased, or as backup power sources, or even among the general populace providing electrical power for outdoor lighting or nighttime food stalls.

By the mid-1960s, Honda had become the dominate player in motorcycle World Grand Prix racing, leading to increased exports of its production motorcycles. Honda also began competing in Formula One racing soon after the release of its first production cars, the T360 mini truck and S360 sports car. Just as with the timing of its tillers and generators, Honda began to set its sights on the worldwide distribution of its general-purpose products, and soon reached an important turning point in its quest for globalization.

As the nations of Southeast Asia were beginning to modernize and develop, they soon found need for cheap yet durable power sources. European or American diesel and two-stroke engines were already in wide use in Southeast Asia at the time, but Honda figured that it could supply cleaner and more compact 4-stroke engines that offered excellent performance and durability.

Honda’s G series of full-scale general purpose engines could be seen hard at work not only in Japan, but around the world.

In 1963, Honda decided to release the G20 and G30 general-purpose engines as lightweight and compact models that could be put to a wide range of uses. These were practical general-purpose engines that had been thoroughly designed for all-purpose use, with no compromises in the important areas of durability and reliability, and soon became an important part of daily life in applications such as outboard motors, generators, pumps and more.

Around the same time, Honda’s tillers and generators were also beginning to be exported to Europe, the United States, Australia, Africa and other regions, and by 1967 general-purpose engines and related Power Products made up fully 70% of Honda's total exports.

In 1968, to cope with the rapid growth of its general-purpose Power Products division, Honda switched to a fully integrated production system that incorporated research and development, planning and design, and production and sales. In 1969, the total cumulative production of Honda general-purpose power products surpassed 1 million units. As production numbers increased, greater effort was put into expanding the lineup to cope with the diversifying needs of users worldwide, and setting the scene for the age of expansion that soon followed in the 1970s.

1970 – 1990

Japan’s economy rapidly expanded throughout the 1960s period of high economic growth. Development of the country’s domestic infrastructure saw steady growth, while people’s lifestyles also greatly improved. By the 1970s Honda was setting its sights on markets outside Japan.

Honda had been exporting its power products since 1963. However, it was now beginning to formulate plans for what it called a ‘Million-Seller Engine’ (ME) for the international general-purpose engine market, which then totaled around 10 million units. With an annual production output of about 200,000 units, Honda was now planning to achieve annual sales of a million or more.

At the time, American-made general-purpose engines accounted for approximately 80% of the global market. These engines took advantage of the merits of mass production to sell at low prices. Yet problems persisted in terms of durability and maintenance.

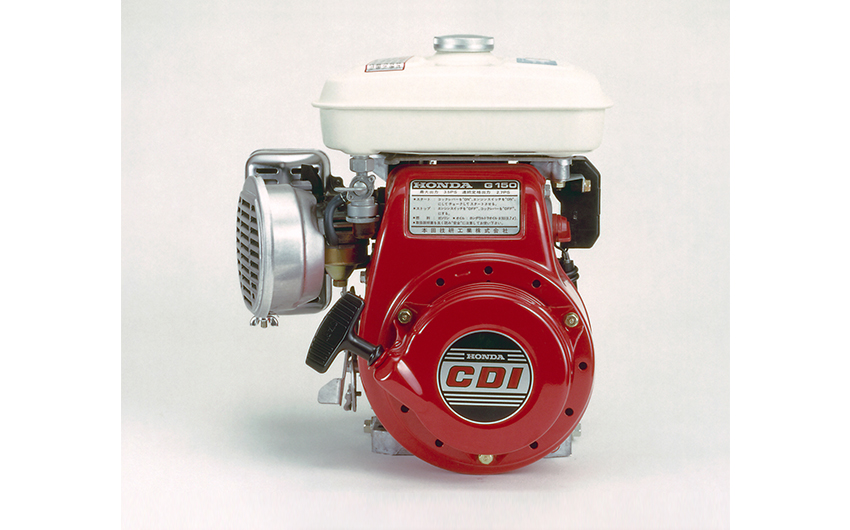

Then, in 1977, Honda released its G150/200 general-purpose engine, the first developed under the new ME concept. The G150/200 incorporated new materials and new designs. With features like an automatic shutoff function for when oil volume was too low, a maintenance-free CDI ignition, a decompression cam for easier starts, and a kill switch for quick stops in emergencies, this engine successfully overcame virtually all of the weak points that plagued mainstream engines.

The G150/200 soon won a highly favorable reputation throughout Southeast Asia, where it became known as the red-and-white engine that steadily sold even when not displayed in the storefront, and found use in a wide variety of applications, including as an outboard motor and for powering pumps.

The engines developed under the ME concept eventually became a full lineup, and finally achieved the goal of a million units in annual sales by 1982. While this was only a tenth of the global market, it successfully showed the world Honda’s superior technological capabilities and vision.

Next on the horizon for Honda were lawnmowers for the US market. First, local needs were thoroughly investigated with detailed field surveys. Technology teamed up with novel ideas to overcome problems, and succeeded in creating a new line of high-quality products that offered excellent durability and ease of use. Honda’s hallmarks of quality were now extending to the United States.

Having worked to solve the issues that most concerned customers, such as starting ease and performance, durability and quietness, these efforts culminated in the 1978 release of the HR21 walk-behind lawnmower, the first of its kind for Honda.

The HR21 was also equipped with a revolutionary safety device called the blade brake clutch (BBC) mechanism. With this mechanism the blades would only turn, and the lawnmower would only move forward, while the user gripped the clutch lever on the handlebar. Whenever the user let go of the handlebar, the blades would stop spinning within three seconds. American consumers had a strong desire to see safety devices incorporated into lawnmowers, but complicated technological obstacles prevented their adoption by existing models. Honda lawnmowers became an overnight success with US consumers, turning the HR21 into a major Honda product.

Honda’s challenge was not just developing and selling unfamiliar new products to unfamiliar countries overseas, nor limited to merely satisfying the needs of its customers, it was also determined to continue taking the initiative in pursuing technological advances. A prime example was the BBC mechanism developed for the HR21, which became a standard safety feature on lawnmowers across the US and made a notable contribution to society.

The next challenge was creating an engine for original equipment manufacturers (OEMs). OEMs produce products to be used in other companies’ brands. Nearly all power product engines are supplied by manufacturers OEM-style. OEM-supplied engines generally remained unchanged unless major problems developed, making it hard to get into the market unless some revolutionary technology was adopted.

The 1970s were rocked by oil crises and the US introduction of the Clean Air Act (also known as the Muskie Act) that instituted strict exhaust gas regulations and heralded a new focus on issues of energy conservation and greener products. Honda's automotive division had developed the compound vortex controlled combustion (CVCC) engine, which complied with the Clean Air Act and demonstrated Honda’s technological prowess to the world.

Now Honda set its sights on making general-purpose engines that would be powerful, fuel efficient, quiet, and environmentally friendly. Thus was born the Zillion Engine (ZE) concept — zillion simply meaning a limitless number.

At the time, the majority of general-purpose 4-stroke engines were of the simple side valve (SV) configuration. However, overhead valve (OHV) designs were vastly superior to SVs in regards to their power output, fuel efficiency, durability, quietness and reliability. The main problems with OHV engines were considered to be their increased size and larger number of parts. Honda boldly decided to take on the challenge of creating an all-new type of OHV engine.

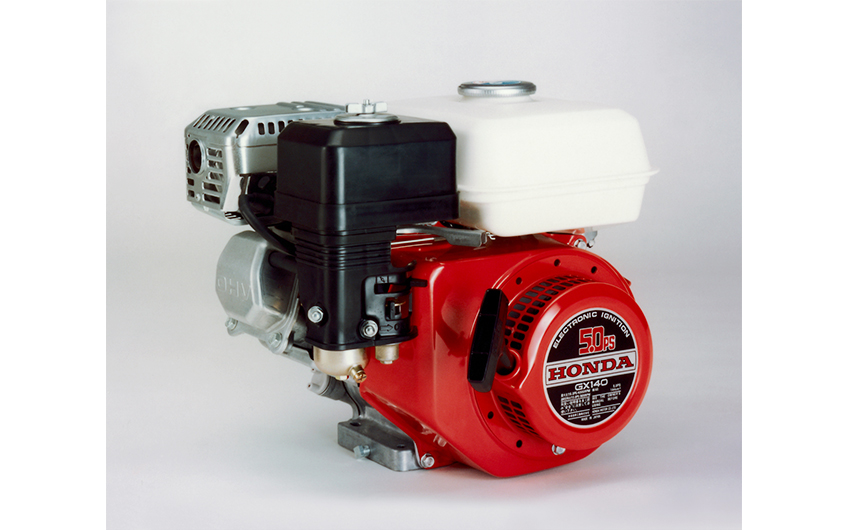

In 1983, the company released its GX110/GX140 engine. The GX110/GX140 achieved success with its inclined cylinder and consolidated parts. Every aspect of this engine surpassed the competition with not just with slight differences, but major leaps forward, while still managing to maintain a competitive price point.

The inclined cylinder design of Honda’s OHV GX series of general-purpose engines was eventually adopted by other manufacturers to become the industry standard for OEM engines, marking yet another revolutionary change to the industry.

By 1981, Honda’s total production output of power products reached the 5 million mark. It had taken thirty years to achieve this figure, yet in the space of the ensuing four years, that number shot up to over 10 million units. This major expansion in demand for Honda Power Products lead to the opening of a lawnmower plant in the USA in 1984. Production outside of Japan mushroomed, and soon spread to France in 1986, Thailand in 1987, Australia in 1988, and then on to India and other countries.

From the 1970s through to the early 1980s, Honda’s Power Products business undertook the challenges of new global markets. Its ability to create innovative products through its advanced technological capabilities as well as its innovative ideas and unique vision won the company a reputation for excellence worldwide, and established its high level of quality and durability as new standards for the industry. As it entered the 1990s, Honda would once again boldly rise to the challenge of surmounting the new hurdles it set for itself, all the while boldly challenging the new issues of environmental protection.

1990 – 2010

Entering the 1990s, environmental issues really began to grab attention on a global scale. With the goal of establishing a high global standard for reduced exhaust gas emissions, Honda independently created its e-SPEC mark to highlight the green technology built into its general-purpose engines. This label was attached to all general-purpose engines and power products that cleared United States’ EPA (Environmental Protection Agency) Phase 3 regulations, the most stringent exhaust gas regulations in the world. Demonstrating Honda’s commitment to leaving a healthy natural environment for future generations, this mark stood as proof that its general-purpose gasoline engines could clear the world’s highest standards for clean power production.

1997, Honda released the super-compact GX22/31 4-stroke engine, the world’s first 360° inclinable model. Until its release, it was widely assumed to be structurally impossible for a 4-stroke engine to continue operating smoothly when turned at any angle. Yet the GX22/31 engine achieved the feat of being a clean and quiet 4-stroke engine that proved to be ideal for powering handheld equipment like brush cutters and power sprayers.

In 2002, the GX22/31 was reconfigured with an overhead camshaft (OHC) and became the GX25. This model continued to feature 360° tiltability and, weighing in at just 2.78kg, went on sale as the world’s lightest-ever 4-stroke engine.

Honda’s GX series of OHV (overhead valve) engines—which had become the industry standard for OEM-supplied engines—adapted to the constant need for better environmental performance to become the GC/GCV series in 1997. By adopting independently developed technology like the world’s first oil-immersed OHC timing belt and a Uniblock cylinder, it became possible to supply high-performance engines offering superior fuel efficiency at low prices to both OEM makers and the general public.

In 2005, Honda released the iGX series of high-output engines offering high-functionality for the OEM market. Incorporating the world’s first electronic engine speed control technology in its new STR governor, the intelligent iGX series greatly expanded the possibilities for the next generation of general-purpose engines.

Honda’s GX, GC and iGX series of engines all cleared U.S. EPA Phase 3 regulations, said to be the strictest environmental regulations in the world, as well as CARB (California Air Resources Board) Tier II regulations. Honda’s remarkable technological expertise shocked the world.

In the world of portable generators, the increasing sophistication of electronic products, combined with the shift to digital, lead to increasing demand for electrical output with a steady waveform.

Honda’s response was to release the GENE 21 series of next-generation portable generators in 1998. Incorporating the world’s first microcomputer-controlled sine wave inverter, this series was able to provide high-quality electrical output like that available in most homes. Other innovative technologies like the eco throttle helped these engines resolve the conflicting issues of high power output and low fuel consumption while coming in at half the weight of earlier models, and with much quieter operation. The GENE 21 series soon won a reputation for excellence as a new generation of power generators.

In 2009, Honda released the Pianta FV200 gas-powered mini-tiller, which ran on widely available butane gas canisters that were easier to purchase, use and store than gasoline. The Pianta FV200 was designed as an entry-level model for home gardens, and fully ninety percent of its owners have been first-time users of tillers, opening up a previously untapped market.

The ENEPO EU9iGB gas-powered generator released the following year featured superior specifications, yet also expanded sales among ordinary households due to its convenient use of butane gas canisters.

Honda was also beginning development of electrically powered products. Released in 2001, the Snowla HS1390i was the world’s first hybrid snowblower, using a gasoline engine to power the blower while its tracks were driven by an electric motor. Automated speed controls allowed it to be easily used by people unfamiliar with snowblower operation, and provided a valuable labor-saving tool in Japan’s snow country, which had been hit hard by depopulation resulting from decreasing birthrates and an aging population. Honda went on to release the Yukios-e in 2014, an easy-to-use electrically powered blade-type snow blower that helped in the mechanization of snow clearance on narrow roads or in shopping areas.

In September of 2017, sales began in Japan of the LiB-AID E500, an electrical storage device, or power bank, developed under the new concept of creating a portable way to carry a full electrical charge. Equipped with Honda’s unique sine wave inverter technology, the LiB-AID E500 provides ‘clean’ high-quality electricity, and has attracted widespread attention as a portable power source that can be freely used wherever the user happens to be, such as inside a car.

In 2012, Honda also released the Miimo robotic lawnmower in Europe. This was a fully automatic lawnmower that not only mows grass, but also charges itself. All the user has to do is set the lawn height. Waterproof, quiet-operating, and with safety features like emergency shutdown, the Miimo can be left to look after lawns with full peace of mind. The Miimo represents a significant step forward toward the future of Honda Power Products, combining electrical power with computerized control.

Starting from a simple auxiliary engine created out of the deprivation of post-war Japan to give power to bicycles, and the H-type engine that marked the beginning of its involvement in power products development, Honda has consistently pursued innovation through technology and ideas to deliver products that offer better performance while being easier to use.

As a result, Honda has built a solid reputation around the world for producing high performance products that are simple to use and don’t break down.

The roots of this success lead directly back to the concept of “making people’s lives better through technology.” Driven by this enduring desire from its very foundation, Honda Power Products will continue to pursue new possibilities well into the future.